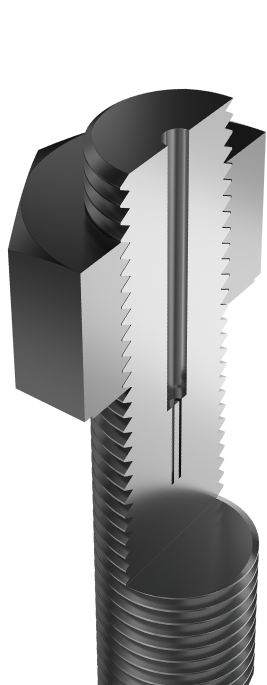

The RT-Bolts worked very well! We were very impressed with the repeatability of the measurements. I have spent years personally doing elongation readings on nuclear reactor pressure vessel (RPV’s) with floating measuring rods. The scatter in those RPV stud measurements was manageable when careful, but I have always found the vulnerabilities concerning. Dirt, grime, surface conditions and centering issues all conspire to create undesirable levels of scatter. The RT bolt scatter, even on this test that created oxidation and scaling was at least as good as what I have experienced with the most well-controlled laboratory measuring rods. Additionally normalizing on strain allows for a tremendously worthwhile simplification of the measurement analysis.

RT-Bolt engineers are the leading foremost authorities on bolted joints, let us support you throughout your project.

- Application Reviews

- Procedural Reviews

- Material Reviews

- Installation equipment Reviews

- Vendor Support

- On Site Support

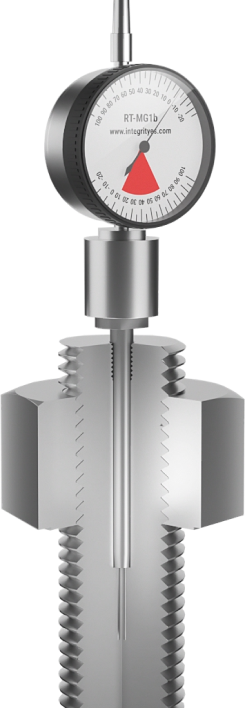

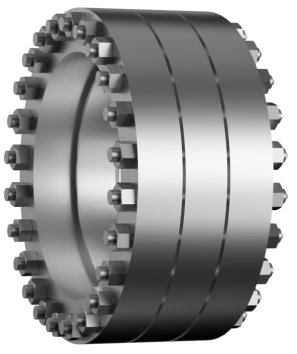

Independently verified to be the most accurate and robust bolt load

monitoring system on the market, even under extreme conditions.

- Bureau Veritas Tested

- Accuracy

- Effect of Impact

- Variability

- Effect of Bolt Bending

- Effect of Nut Position

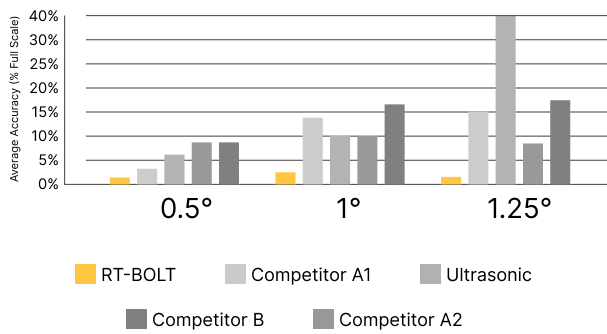

RT-Bolt has undergone rigorous testing to ensure accuracy in any application. Independently verified by Bureau Veritas as the most precise and robust solution for bolt load monitoring, RT-Bolt has been proven to excel in extreme temperatures and conditions. Repeatability, user error, bolt bending, impact and nut position all exhaustively tested to guarantee premium performance every time. Trust RT-Bolt for unparalleled accuracy and dependability.

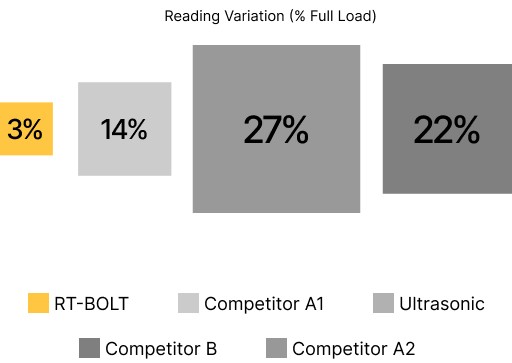

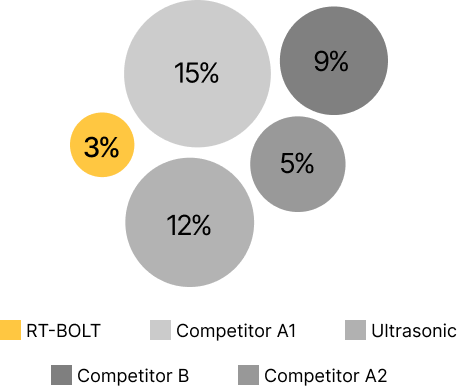

The general accuracy and repeatability of each unit under workshop operating conditions. RT-Bolt maintained the highest accuracy of all tested products.

![]()

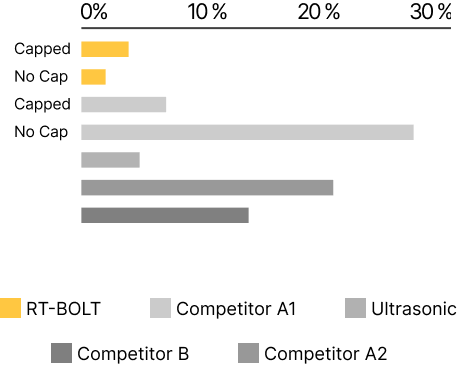

dropped or struck with a spanner or wrench while installed.

RT-Bolt was the most accurate, even after

repeated severe impacts on the bolt.

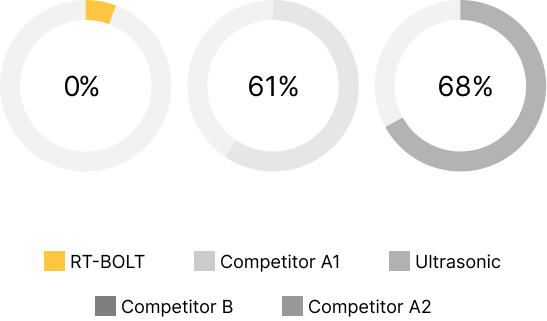

RT-Bolt was the most accurate by comparison to all other methods.